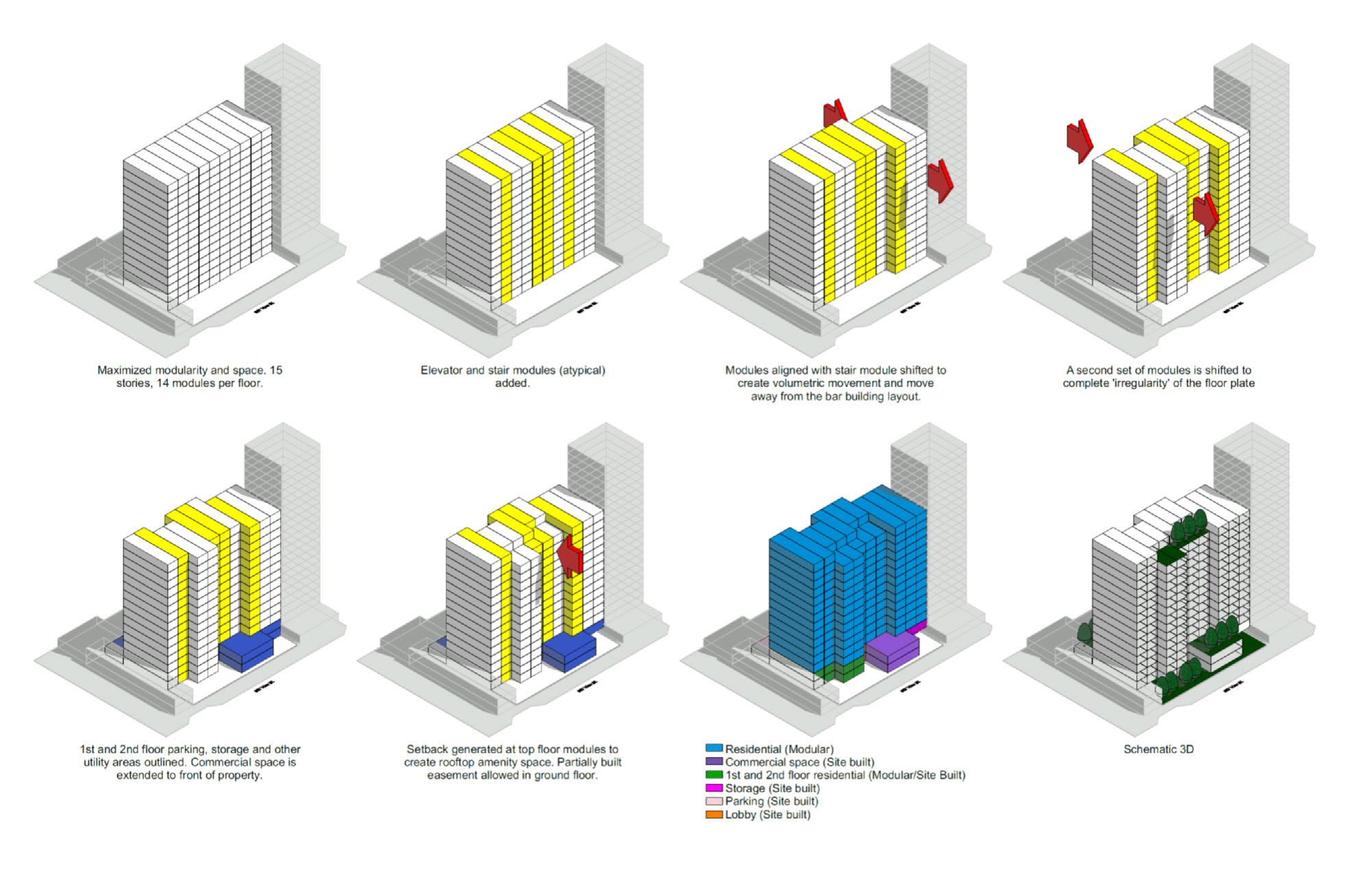

Development of the Second Generation System

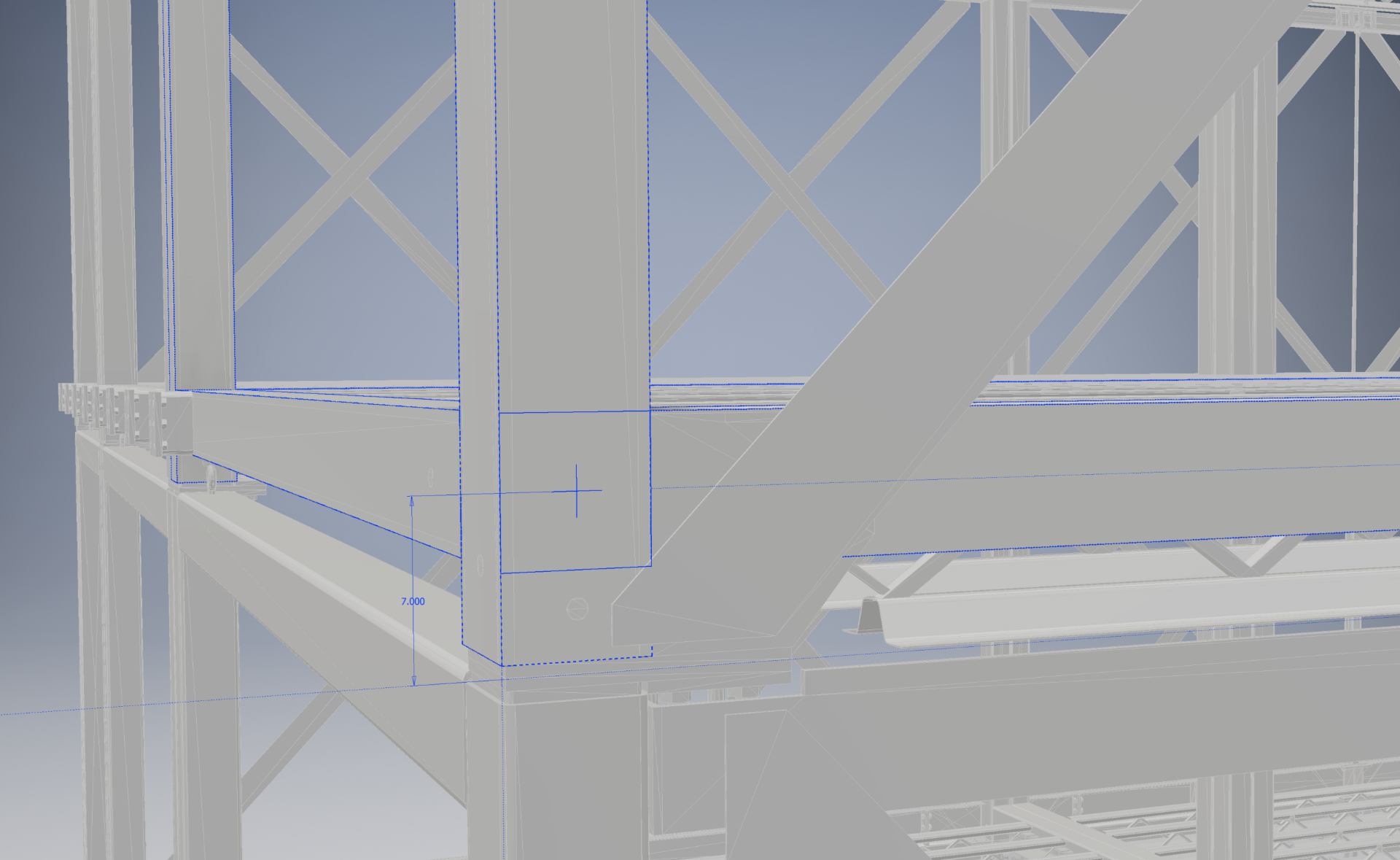

Our second generation system featured an improved frame, bracing, floor structure and connector..

Our second generation system did not conform to ISO container standards and therefore flexible dimensions of the modules were possible, leading to more flexible building configurations.

The second generation system was again rated non-combustible and due to the improved connectors, could be configured for higher buildings, in 1-hour and 2-hour fire ratings.

Testing

We conducted several types of tests at the factory.

Once the frames of the modules were considered structurally complete, we conducted stacking tests, road transportation tests.

We also conducted separate stacking tests to observe the real-life functionality of our modular building envelope components.

Rapid Site Assembly

With our second generation connectors, modules are designed to effortlessly engage with one another for rapid site assembly.

More Info